Intergraph Smart Instrumentation Revision

Data Migration and Transformation

Summary

This service provides a solution for the revision of Intergraph Smart Instrumentation drawings and data to match mark-ups resulting from engineering changes or as-building activities.

Differentiators

- Extensive Intergraph Smart Instrumentation expertise and experience

- Advanced application knowledge accelerates delivery

- Best practice knowledge and consulting advice

Challenges

The revision of Intergraph Smart Instrumentation drawings and data to match mark-ups is a labour-intensive activity that is often deferred or delayed due to a lack of qualified resources. Such deferrals result in an electronic data set that is increasingly inaccurate and reduces the value of the investment in the technology.

Deliverables

Our services may be delivered in an online mode, where our team will remotely access your production software and database minimizing downtime, or offline, with us submitting a revised database snapshot upon completion for more complex projects.

In either mode, the range of data and drawings which may be revised include:

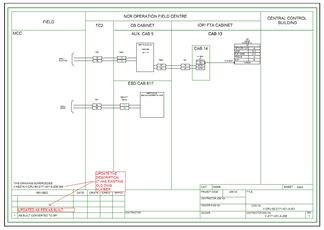

- Instrument index and loop drawings

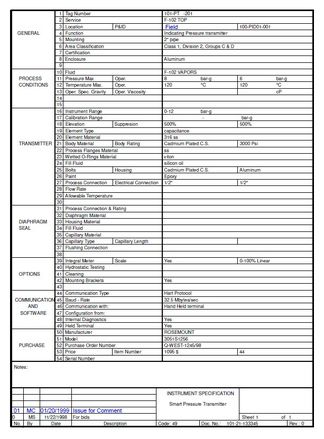

- Process and instrument data sheets

- I/O lists and instrument field wiring

- Junction box and marshalling cabinet wiring diagrams

- Cable and junction box schedules

Work Process

Our detailed work process varies to suit project requirements; however, the following steps are typical once the input data, drawings and mark-ups are received:

- Review mark-ups and update reference data if necessary

- Clarify any queries relating to marked-up changes with the client

- Incorporate changes into the Intergraph Smart Instrumentation database

- Extract reports and snapshot drawings to perform quality checks and corrections

- Submit a project backup, reports and drawings to the client for review

- Conduct final project handover and production deployment into the client environment

Quality Assurance

TecSurge uses a combination of peer review and automated data and rule checks to verify the quality of our workmanship. A final check involves one-for-one comparison of each completed deliverable against its source, to ensure an accurate and complete reproduction is produced.

In addition, we extract all drawings and relevant reports for review by our client prior to incorporating the new or modified drawings into the production environment, to reduce any risks of misinterpretation and to minimize disruption to ongoing operations.

If this service describes your situation, please contact us today for a quotation.