Piping Specification Writing

Specification and Catalogues

Summary

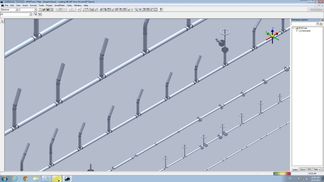

Under this service, TecSurge creates and delivers piping specification and catalogue data for use in 3D modelling environments such as AutoCAD Plant 3D, Bentley OpenPlant and AutoPLANT, Hexagon PPM CADWorx, Smart 3D and PDS, and AVEVA PDMS and Everything3D. Our deliverables are based upon engineering specifications, datasheets and other source information provided by our clients, as well industry standards (such as ASME, BS, DIN, JIS, etc.) and supplier or vendor information.

Differentiators

- High-quality, “right first time” results, due to automation and thorough quality control

- Years of experience with piping modelling systems, ensuring high end-user productivity

- Ability to meet aggressive project schedules with efficient and flexible workforce

Deliverables

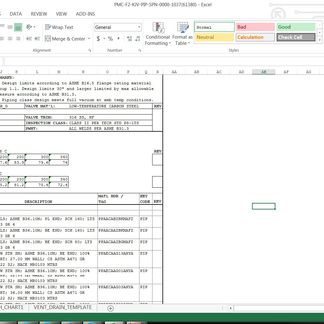

The primary deliverables from this service consist of data files which can be imported directly into the target plant design systems, such as:

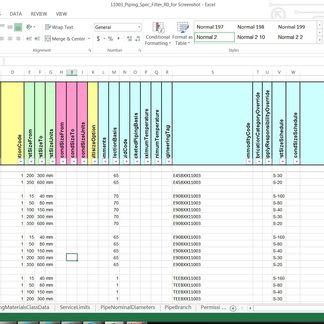

- Excel bulk load sheets for Smart 3D

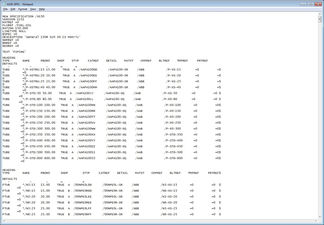

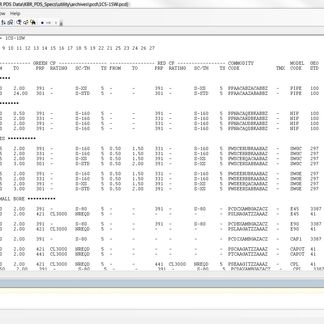

- PCD, PMC and description library text files for PDS

- Specification Data for PDMS

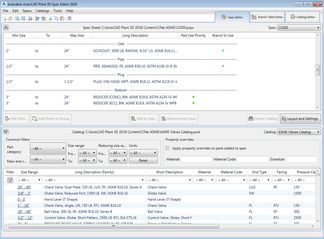

- Pspx, pspc, pcat and dwg files for AutoCAD Plant 3D

- Microsoft Access database files for OpenPlant and AutoPLANT

In addition to these primary deliverables, secondary deliverables such as quality and project management reports are prepared and provided to the client as part of the service.

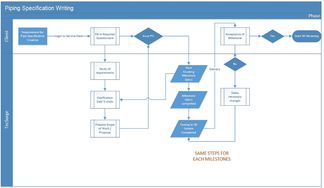

Work Process

TecSurge manages the execution of Piping Specification Writing as a professional services project, involving a dedicated project manager and our expert services team. Typically, the project schedule will be organised and based upon milestones aligned with our client’s project priorities (for example, a project may require standard carbon-steel piping specifications to be delivered first, while exotic or vendor piping specifications have a lower priority).

These priorities and deliverables associated with each of the project milestones are agreed with the client during the project kick-off meeting, after which the detailed execution commences. As each milestone is reached, a further set of fully quality checked, ready for use piping specifications is delivered, along with a project status report.

Specifications may be created using a variety of in-house automation tools, or using commercial software such as Intergraph SmartPlant Reference Data. Clarifications or queries are resolved by discussion with the client, either by conference call or email, depending upon the nature of the issue.

Quality Assurance:

TecSurge ensures that the piping specification data issued as project deliverables matches the input engineering specifications provided by the client. In addition, specification reports and other deliverables are generated from SmartPlant Reference Data (or client in-house systems) and provided to clients for verification and acceptance.

TecSurge guarantees that the specifications prepared for use in 3D modelling systems are 100% accurate according to the source data provided. TecSurge also ensures all piping components are ready for use and can be placed within the 3D environment by using the standard application “consistency checking” features, and automating placement testing, using software tools such as CAXperts Spec Tester and Spec Manager.

Getting Started

In a typical scenario, our clients require piping specifications to be prepared and tested for use in a 3D piping design system for an upcoming project.

Usually, our client has in-house materials and piping engineering expertise, necessary for the creation of the source engineering specifications (sometimes referred to as a “paper” or “written” specification), including references to standards and vendor information for dimensional data.

From here, specialist expertise is needed to transform these engineering specifications to the format required by the 3D system. TecSurge offers this specialist expertise as a high-quality, reliable and fit for purpose professional service.

To understand the scope of the work, we typically ask a series of questions, such as:

- How many piping specifications are required?

Why: Obviously this question will have a significant impact upon the scope of the project, however counter-intuitively, due to the use of common components between specifications, the time required to prepare additional specifications can decrease as the number of specifications increases. - What types of piping specification are required?

Examples include: ANSI/ASME with ASTM, BS, DIN, JIS, non-standard or vendor systems, jacketed or lined, non-metallic, flanged or Victaulic, etc.?

Why: Specifications which are based upon industry standards typically take less time, while those based upon vendor or non-standard systems may require additional effort to capture accurate catalogue data. - When is your target completion date, and when do you expect to start?

Why: The responses to these standard project management parameters can have a significant impact on the cost due to the prioritisation of work and the manpower required. - What system should be used for specification preparation?

Native, SmartPlant Reference Data, Other (please specify)

Why: The choice of specification creation and management system can have an impact upon the project execution time due to differences in the tools themselves.

If this service describes your situation, and you’re able to provide the engineering inputs and answers to the questions listed here, contact us today for a quotation for Piping Specification Writing.