Data Consistency Checking for SmartPlant Instrumentation

Analytics, Quality and Auditing

Summary

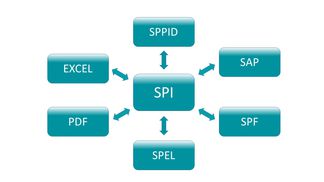

This TecSurge service delivers a cost effective solution for checking and correcting data in a SmartPlant Instrumentation (SPI) database. The process considers both existing data and physical documentation, via automated and manual methods. A wide range of data sources such as SmartPlant P&ID, SmartPlant Electrical, Smart 3D and other engineering systems or databases are used in the comparison and checking process.

Differentiators

- Proprietary in-house automation delivers efficiency and high quality results

- Excellent knowledge of SmartPlant Instrumentation and its practical application

- Experience working with a wide range of project and legacy data deliverables and formats, for both EPC and owner-operator organisations

Deliverables

Under this service, TecSurge typically delivers data to the customer using the SQL Anywhere data interchange format supported natively by SPI. This allows customers to easily merge the captured data into an existing SPI database, including elements such as:

- Customised instrument profiles

- Customised specification forms

- Imported instruments

- Imported instrument data sheets

We also support other methods of updating SPI data. For “owner” type domains with existing projects or SPI links to SPF/SPO, SPI importing can be done with local or remote access to the database.

Work Process

TecSurge’s work process for this service consists of the following general steps:

- Develop data consistency matrix to define the information that must be checked and compared.

- Collection of data from data sources.

- Organisation of data and raw data quality check

- Data consistency comparison and checking

- Data inconsistency report and action list

- Data correction and update

- Final quality and performance checks

If this service describes your situation, please contact us today for a quotation on Data Consistency Checking in SmartPlant Instrumentation.