Data Sheet Capture for SmartPlant Instrumentation

Data Migration and Transformation

Summary

This TecSurge service delivers a cost effective, one time solution for capturing instrument data sheet information from various source formats into SmartPlant Instrumentation (SPI).

Differentiators

- Excellent working knowledge of SmartPlant Instrumentation and its practical application, as well as experience working with project and legacy data deliverables and formats, for both EPC and owner-operator organisations

- Proprietary in-house automation delivers efficiency and high quality results

- Flexibility and scalability to meet different scenarios, with reliable and cost-effective service delivery

Challenges

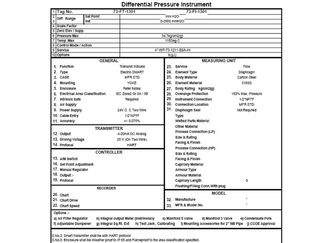

There are a number of factors which can lead to instrumentation data being provided to the end user in hard-copy, Excel or PDF format, rather than handed over in a directly usable SmartPlant Instrumentation database.

For customers with an existing SPI implementation, retaining information in such formats while continuing to operate the SPI application can lead to many inefficiencies and duplication, problems which will only increase in severity over time.

Capturing such data from its supplied format into SPI is typically not able to be automated, and therefore requires a quality controlled, cost effective approach to data entry.

Deliverables

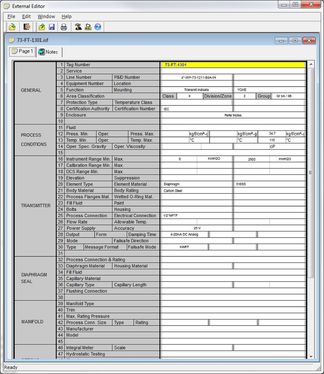

Under this service, TecSurge typically delivers data to the customer using the SQL Anywhere data interchange format supported natively by SPI. This allows customers to easily merge the captured data into an existing SPI database, including elements such as:

- Customised instrument profiles

- Customised specification forms

- Imported instruments

- Imported instrument data sheets

Work Process

TecSurge’s work process for this service consists of the following general steps:

- Collection of data sources

- Organisation of data and raw data quality check

- Development of instrument profiles

- Customisation of specification forms

- Data entry of raw data into SPI

- Final quality and performance checks

Quality Assurance

TecSurge utilises a two stage checking process to ensure the quality of the service delivery.

Before the source data is input, various checks are performed depending upon the source data format. For example, if source information is in a scanned format, OCR tools are used and the results of the OCR processing compared manually against the source data. Data obtained from structured electronic sources such as Excel spreadsheets or Access databases can be verified programmatically. Specific aspects of the data which are subject to quality checking include:

- Instrument tag and loop number

- Process information

- Instrument specification data

- Data value units of measure

- Selection list values

Final verification of the delivery is performed by the customer, and final approval of the work constitutes technical acceptance.

Getting Started

In order to estimate the schedule and cost for this service, we require the following information:

- Quantity of instrument tags and instrument types to be captured

Why: The quantity of instrument tags is directly proportional to the man-hour requirement. Grouping instruments by type simplifies the process and leads to maximum efficiency. - Information about the source data format.

Why: Data existing in Excel files is easier to manipulate that scanned images or PDF. Where possible, TecSurge will apply automation to deliver the best quality and most efficient outcome, and higher-quality data formats will permit greater use of such technology, producing a faster and cheaper result. - Database server and SPI version required

Why: TecSurge will utilise the identical SPI software version and database platform as the end customer, to guarantee a 100% compatible deliverable.

If this service describes your situation, and you’re able to provide the engineering inputs and answers to the questions listed here, contact us today for a quotation for Data Sheet Capture for SmartPlant Instrumentation.