Plant Drawing Migration from PDS to SmartPlant 3D

Drawings, reports and datasheets & Data Migration and Transformation

Customer Benefits

- Reduced risk by fixed price contract

- High quality through automation and thorough checking

- Short schedule due to experience, expertise and scalable methodology

Our Services

Consulting, SmartPlant 3D isometric and arrangement drawing template development, fit for purpose automation development, manual drawing retouching and quality checking.

The Client

The client’s company was founded as the first engineering firm in Korea in 1970 and has its headquarters based in Seoul, South Korea. As an Engineering, Procurement and Construction (EPC) Company, it provides a full range of engineering services including feasibility studies, design, procurement, construction, and commissioning. The company has substantial business in over 40 countries worldwide, with an established presence in countries such as Saudi Arabia, United Arab Emirates, Algeria, India, Thailand, Trinidad & Tobago, and Mexico.

Project Challenge

Our client executed the detailed design and engineering for a major refinery expansion project using PDS, and subsequently migrated the model data from PDS to SmartPlant 3D in order to meet the contractual handover specification.

In order to complete the handover, our client also needed to migrate bills of material, piping isometrics and general arrangement drawings from PDS to SmartPlant 3D.

Our client requested a proposal from TecSurge to migrate these deliverables from their original PDS format to the SmartPlant 3D environment required for handover.

In addition, the client requested that TecSurge make changes to the SmartPlant 3D model required to eliminate drawing generation errors, and clear model to-do list entries.

Our Solution

TecSurge received the customer’s existing PDS deliverables, performed an analysis and proposed a solution involving an automated process combined with manual retouching to address certain specific cases which could not be handled automatically.

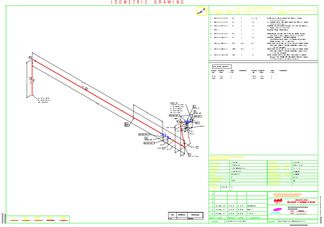

TecSurge provided advice including the best method for updating bolt lengths, pipe line list, insulation and title block revision information in the SP3D isometric drawings necessary to match the original PDS drawings.

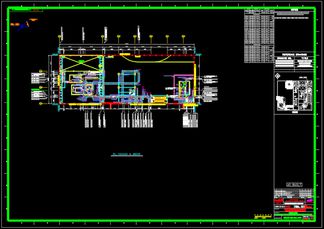

For general arrangement drawings, TecSurge created view styles and label and dimension styles to match each of the PDS drawing types, and then prepared an initial drawing template for each type of drawing and send to the client for approval.

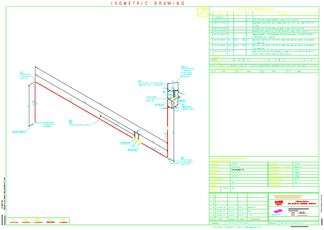

Once approval to proceed was obtained, TecSurge executed the work using in-house automation and expertise, generating 24,340 isometric and 545 general arrangement drawings. In addition, TecSurge resolved all drawing generation errors, and cleared open to-do list entries from the SP3D environment. TecSurge developed proprietary tools to automate the following steps while migrating general arrangement drawings from PDS to SP3D:

- Composed drawing creation

- Drawing volume creation

- View creation, including assignment of view style, direction and scale

- Association of drawing volume to view

- Title block completion

After the automated process was completed, TecSurge performed manual retouching as required, followed by a quality checking process prior to client handover.

If this example describes your situation, contact us today for Plant Drawing Migration from PDS to SmartPlant 3D.