SmartPlant Enterprise Integration

Systems implementation and integration

Summary

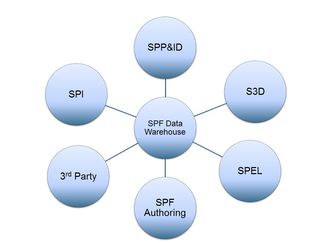

Intergraph’s SmartPlant Enterprise solution includes an integration platform, supporting the collaboration and data reuse capabilities essential to complex modern engineering projects.

TecSurge offers the expertise and experience necessary to guide and assist clients to implement SmartPlant Enterprise Integration. We address the full range of solution capabilities such as data warehousing and consolidation, document management and collaboration, workflow and the entire publish and retrieve information management lifecycle.

Our expertise covers applications including SmartPlant Materials, SmartPlant Instrumentation (SPI), Smart 3D (S3D), SmartPlant P&ID (SPP&ID), SmartPlant Electrical (SPEL), SmartPlant Isometrics and PDS, as well as 3rd party solutions such as SAP, Maximo and Documentum. This expert application knowledge combines with our SmartPlant Foundation expertise upon which the full integrated environment is constructed.

TecSurge’s SmartPlant Enterprise Integration service provides consulting, design, configuration, customer specific software development & testing, training and handover.

Differentiators

- Pragmatic advice and guidance

- Extensive product experience including custom development

- Fixed price, turn-key delivery

- Intergraph SmartPlant Enterprise certified resources

Deliverables

We execute SmartPlant Enterprise Integration projects by dividing the implementation into work packages. One of the important goals of this work pack organization is to logically divide the SPE data model so that it will be flexible and easy to maintain the resulting solution. This work pack organization will also help in building a system quickly starting from a blank dataset.

TecSurge typically separates work packages based upon the target integrated application such as SPI, S3D, SPP&ID, and SPEL.

Each work package ultimately results in a set of load files and custom dynamic-link libraries (dll’s) based on the customer’s requirements to build the system and make it fit for use. The work package that TecSurge delivers allows making additions or deletions.

SPI: In integrated mode, SPI can publish instrument tags, cabinets, I/O data, dimensional data and loop data, and retrieve equipment data, piping data, instrument data, loop data, electrical I/O control signals, electrical equipment and the plant breakdown structure from SmartPlant Foundation.

S3D: Smart 3D is able to publish cables, conduit, duct, equipment, material take off data, piping data, instrument data, structural data and hanger data, and retrieve instrument data, equipment data, piping data, cable data and the plant breakdown structure from SmartPlant Foundation.

SPP&ID: SmartPlant P&ID can publish equipment data, vessel data, nozzle data, piping data, instrumentation data, loop information, control system function and signal data and retrieve instrument tags, loop data and Aspen basic engineering data from SmartPlant Foundation.

SPEL: SmartPlant Electrical can retrieve cable data, instrument and cabinet data, I/O signals and equipment data from SmartPlant Foundation, and can publish cable schedules, electrical equipment, instrument, electrical I/O (control), cabinet and junction box data.

Work Process

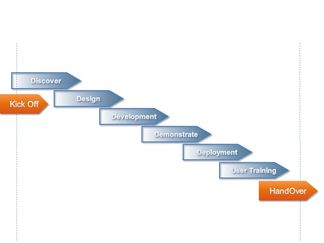

We follow a structured work process, which typically begins with our consultants conducting a requirements gathering workshop. This workshop allows us to understand our client’s requirements, and begin to explain and propose possible high-level solutions based on our experience and pragmatic approach.

Following the initial requirement gathering, TecSurge prepares requirements documentation and develops a project plan to define the project phases and schedule.

We apply an iterative approach during project execution, in which we involve the client closely by holding demonstrations and capturing feedback at each review milestone. At the end of each phase we validate the initial requirements, and work with the client to update where necessary. This process ensures that our clients receive a solution that works for them in practice, not just in theory, and that there are no surprises with respect to time, cost or quality.

Once the iterative development and demonstration cycle reaches a logical milestone, TecSurge deploys the work packages to the customer environment and performs user training, either via a “train the trainer” approach, or directly hosting classroom training with end users of the solution.

Finally, acceptance testing is performed by the customer, followed by a warranty period during which any last minute corrections can be implemented if necessary.

Quality Assurance

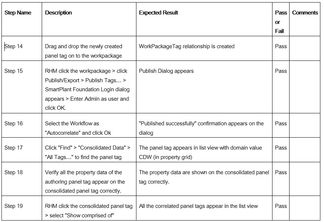

TecSurge ensures the quality of each SmartPlant Enterprise Integration by documenting every possible scenario and testing them thoroughly. The resulting test scripts are delivered to the customer during a User Acceptance Test, which serves as both a final Quality and Performance check.

Our team manages the validation of all possible scenarios across the different work packages implemented for integrating the different SmartPlant tools, namely SPI, S3D, SPP&ID, SPEL and third party solutions such as SAP, Maximo and Documentum with SmartPlant Foundation.

Getting Started

TecSurge is engaged by customers who have selected SmartPlant Enterprise integration. In order to understand the scope of the work, we ask a series of questions, such as:

- What are the tools currently in use including SmartPlant and also other 3rd Party tools and its versions?

Why: This information is used to understand the specific work flow a company follows and to provide best possible solutions for the current scenarios. - What are the priorities of the systems/tools to be up and running?

Why: We follow your priorities to schedule our work and make the systems up and running in that order. For example, you may define that the priority is to have SPI up and running in the integrated environment first, followed by the other tools. - When is your target completion date, and when do you expect to start?

Why: The responses to these standard project management parameters can have a significant impact on the cost due to the prioritisation of work and the manpower required.

If this service describes your situation, and you’re able to provide the engineering inputs and answers to the questions listed here, contact us today for a quotation for SmartPlant Enterprise integration.