Piping specification and catalogue preparation for AVEVA E3D Design

Specification and Catalogues

Summary

TecSurge provides a service in which we prepare and maintain piping specifications and catalogue data for use in 3D modelling environments, such as AVEVA E3D Design (E3D). Our deliverables are based on engineering specifications, datasheets, industry standards (such as ASME, BS, DIN, JIS), and supplier or vendor information.

Differentiators

- Over 40 years of combined team experience with E3D

- Extensive experience with catalogues and specifications

- Deep understanding of engineering design procedures and requirements

- Quality assurance for all delivered catalogues and specification

Deliverables

The primary deliverables from this service consist of data files which can be imported directly into the target plant design systems, such as:

- DABACON databases

- DATAL files

Work Process

TecSurge manages the preparation of catalogues and specifications as a professional services project, involving a dedicated project manager and our expert services team. The project schedule is organised based on milestones aligned with client priorities.

The priorities and deliverables associated with each milestone are approved by the client during the project kick-off meeting, after which the detailed execution commences.

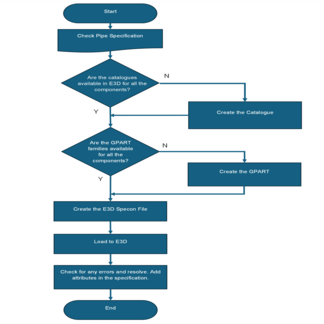

The detailed execution consists of the following steps:

- Verifying reference documents and input data

- Reviewing the input piping specification

- Identifying the GPART family for all components

- Creating Specification Constructor (Specon) files

- Loading and validation in E3D

Verifying Reference Documents and Input Data

Before we kick off the project, it's crucial to meticulously verify all reference documents and input data to ensure we have all the necessary information available. These documents may encompass standards, specifications, and datasheets, vital for creating the E3D elements. By double-checking that the records contain essential details such as dimensional data, weights, density, and other pertinent physical properties, we can ensure a smooth and successful project execution.

In the event of any gaps or unclear points, we will promptly reach out to our client with a comprehensive report, paving the way for the next stage of the project.

Reviewing Piping Specifications

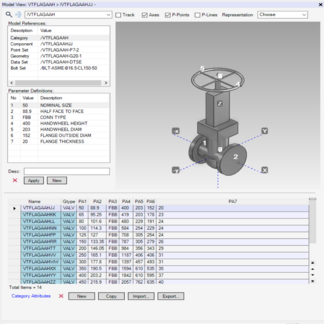

For every geometric component with a unique geometric shape, regardless of the standard or material, there is a corresponding category element (CATE) to be created and assigned with the correct generic type (GTYPE).

TecSurge performs a series of quality reviews to ensure the proper catalogue creation process:

- Check the vendor/reference drawing.

- Create the CATE with the correct GTYPE and geometry that represents the vendor/reference drawing, ensuring all the p-points in the SKEY are correctly defined,

- Create centre lines that represent the component.

- Create the required sizes, ensuring the dimensions are per reference/vendor drawing and the connection is correct.

- Set the correct BOLTSET.

- Validate and update incorrect data.

Identifying GPART Families

To check if there are GPART families for all components, TecSurge performs the following steps:

- Check the component type, material, standard, connection, schedule, and rating among others.

- Generate a commodity code using an automation tool.

- Assign the missing code for the commodity code and acquire the updated Commodity Code System list.

- Create the GPART family.

- Review and revise the GPART family.

- Create the GPART using a tool.

- Update the component weights

Creating Specon Files

Using the Piping Material Specification documents, piping specifications are loaded in the catalogue database using the Specon module from text files with the elements of the specification in a tabular format.

TecSurge performs the following steps in creating Specon files:

- Check if the headings for each component are correct.

- Check if the sizes have been added for each component.

- Check if GPART is available for each component.

- Add miscellaneous items to the specification such as weld and bend.

- Check if the correct attributes are set in the specification.

The files are then loaded into E3D.

Once ready, the catalogues and specifications are delivered along with a project status report.

Quality Assurance

At TecSurge, we ensure that all the catalogues and specifications created for our clients are not only fully functional but also exceed their expectations. We guarantee that all deliverables are based on the verified input data they have provided.

Our quality process includes 3D modelling testing, sample output drawings, reports, and consistency checks using standard application functions. After successful testing, we will send the handover package for client verification. Once our clients confirm acceptance of the catalogues and specifications, we welcome their comments and feedback. Any issues raised will be promptly addressed to ensure a smooth final handover and project completion.

Getting Started

Typically, we require our clients to prepare all the necessary input data/documents (standards, datasheets, specifications) to start the project. TecSurge will review and validate the input data to ensure it contains all necessary information without conflicts. We will also inquire about the following:

-

What version of E3D are you using?

Why: Ensuring full compatibility on different E3D versions and testing in your required environment. -

What types of catalogues and specifications are required?

Why: Different types may affect the time and effort needed for accurate capture of catalogue data. -

When is your target completion date, and when do you expect to start?

Why: Answers to these project management parameters can significantly impact costs.

If this service describes your situation, and you can provide the engineering inputs and answers to the questions listed here, contact us today for a quotation.

Let's talk.