Catalogues and Specifications for PDMS/E3D

Specification and Catalogues

Summary

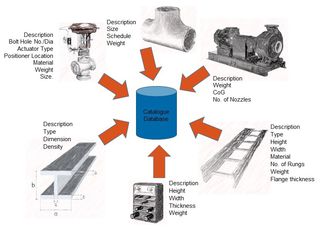

TecSurge builds and maintains catalogues and specifications for 3D modelling in PDMS and E3D environments in accordance with verified engineering specifications, datasheets and reference materials provided by a client.

The catalogues and specifications are designed and created to include valuable information such as text details, materials, physical properties, nuts and bolts or any information used in PDMS/E3D that is required for the output of 2D drawings, bills of material/MTO, isometrics or client specific outputs.

Differentiators

- Greater than 30 years of combined team experience with PDMS/E3D

- Extensive experience with catalogues and specifications using reliable methods in validation of inputs and output verification

- Deep understanding of engineering design procedures and requirements, combined with hands-on practical software experience, minimize delivery schedule and cost

- Quality assurance of all delivered catalogues and specifications to be compatible with different PDMS/E3D environment in the clients’ locations

Deliverables

The primary deliverable from this service is the catalogue database (DATAL) file which typically contains any of the following types of PDMS/E3D catalogue and specification data:

- Piping

- Standard

- Specialty, such as strainers and sight glass

- Instrument/Telecom/Electrical

- In-line, such as control valves, flow meters

- Tray/Ladder

- Multi-Cable Transit (MCT)

- Instrument Equipment templates, such as field instruments with stand

- Electrical Equipment templates, such as transformers and lighting fixtures

- Structural

- Profiles

- Fittings

- Joints

- Penetrations, such as sleeves and doublers

- Access, Stairs and Ladders (ASL) templates

- Mechanical/Safety

- Equipment templates, such as vessel and pumps

- Heating, ventilation and air conditioning (HVAC)

- Equipment templates, such as chillers and condensers

Work Process

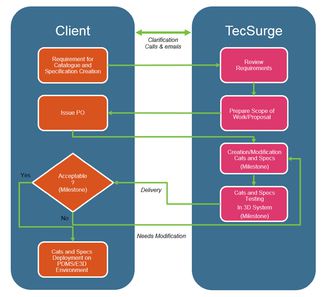

TecSurge manages the execution of catalogues and specifications as a professional services project involving a dedicated project manager and our expert services team. Typically, the project schedule will be organised and based upon project milestones aligned with our client’s project priorities.

For example, the starting phase of a project may require equipment templates to be delivered first for mechanical equipment arrangement and to be followed by piping catalogues and specifications for pipe routing.

These priorities and deliverables associated with each of the project milestones are agreed with the client during the project kick-off meeting, after which the detailed execution commences.

The detailed execution consists of several stages:

- Reference document and input data verification

- Catalogue and template element creation (geometries, points/primitives)

- Specification creation including additional elements, such as SDTEs, SMTEs and Bolt elements

- Catalogue and specification testing and checking in different modules

Reference document and Input Data Verification

Before starting the project all reference documents/input data are verified. This step ensures that there is enough information to complete the project. Documents may include standards, specifications, datasheets, bolt length tables and branch tables. This stage also verifies that the documents contain information necessary for the creation of PDMS/E3D elements, such as dimensional data, weights, density, or any physical properties of a component.

Any clarifications or missing information will be requested from our client in a report format, to permit the commencement of the next stage.

Catalogue and Template element creation

For every geometric component with unique geometric shape, regardless of the standard or material, there is a corresponding category element (CATE) to be created in the CATA database using the PARAGON module. For templates, a corresponding template element (TMPL) is created in the DESI database using the Design module.

Specification creation including additional elements

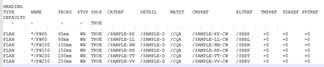

Geometric elements and templates are accessed in the PDMS/E3D model by reference from corresponding specification elements.

Using Piping Material Specification documents, piping specifications are loaded in the catalogue database using the SPECON module from text files with the elements of the specification in a tabular format. Structural and other types of specifications also can use similar methods for loading specifications to the catalogue database.

Aside from specifications, additional elements such as SDTEs, SMTEs, bolt elements and weight information are created and referenced by specifications elements.

Catalogue and Specification testing and checking

To make sure the catalogues and specifications are working properly, TecSurge performs a series of quality tests and checks in different modules as each milestone is reached.

- Model of each component from specification

- Verification of geometry

- Isometric (piping only)

- Verification of the connections

- Verification of the isometric symbols

- Checking of the description and material

- Draft of each modelled component

- Level of representation and obstruction

Ready catalogues and specifications are then delivered along with a project status report.

Quality Assurance

TecSurge ensures that prior to issuing deliverables, every catalogue and specification created for our clients is fully functional and meets our client’s expectations. TecSurge also ensures all the deliverables are in accordance to the verified input data provided by the client.

3D modelling testing, sample output drawings, reports and consistency checks using standard application functions are all incorporated in the quality process. Upon successful testing and checking, the handover package is sent for customer verification. The client then confirms their acceptance of the catalogues and specifications and provides comments and feedback. Any issues raised during this stage will be resolved prior to final handover and project completion.

Getting Started

Typically, our clients have to prepare all the input data/documents (standard, datasheets, specifications…) required to start the project. TecSurge takes care in checking and validating all the input data. Input data are verified if it contains all the necessary information (dimensions, weights…), also if it contradicts with one another.

In addition to these documents which are requested by TecSurge, we will ask our clients a series of questions to clarify the scope of work:

- What version of PDMS/E3D are you using?

- Why: To account for full compatibility on different versions of PDMS/E3D and ensure our testing is performed on an environment required by our client.

- What types of catalogue and specification are required?

- Why: Catalogue and specifications which are based upon industry standards typically take less time, while those based upon vendor or non-standard systems may require additional effort to capture accurate catalogue data.

- When is your target completion date, and when do you expect to start?

- Why: The responses to these standard project management parameters can have a significant impact on the cost due to the prioritisation of work and the manpower required.

If this service describes your situation, and you’re able to provide the engineering inputs and answers to the questions listed here, contact us today for a quotation.