Wiring Diagram and Loop Drawing conversion for SPI

Data migration and transformation

Summary

This TecSurge service provides a cost effective, one time solution for converting tabulated wiring information and 2D CAD drawings into SPI Enhanced Wiring Diagrams and SmartLoops. Converting existing design drawings to the SPI Enhanced Report and consolidating them into a database can greatly improve the plant life cycle information management, and ensure reliable access to current information.

Differentiators

- We have excellent technical knowledge and proficiency with instrumentation design and how it is implemented in SmartPlant Instrumentation.

- TecSurge has years of experience supporting EPC companies as well as Owners/Operators applying SPI in production environments.

- Our service is cost-efficient and flexible to meet specific client scenarios and schedules.

Challenges

Often, suppliers have unique formats and standards for delivering engineering documents. Use of these bespoke formats can cause long-term difficulties for project and client teams. In the hands of unfamiliar staff, wrong interpretation of drawings and documents can lead to expensive mistakes in the field. When instrumentation drawings are imported into SPI, deliverables are standardised, even when the design work is undertaken by different parties.

As the plant ages, process controls need to be upgraded to improve quality, dependability and safety of the plant. The documents delivered by these projects are typically not as pristine as the original document. Over time, such deliverables can progressively become harder to interpret due to document handling techniques such as optical scanning and manual mark-ups. Management of instrumentation design data in SPI eliminates this issue of degradation of document quality, ensuring all deliverables meet the same quality benchmarks as their first issue.

Retention of instrumentation drawings is cumbersome. When dealing with traditional document numbers and document titles as an organisation method, locating references for any project amounts to a significant effort. Using SPI’s tag-document relationships, it is extremely easy to locate documents associated with particular instruments or loops.

Deliverables

This service delivers an SPI database in the standard SQL Anywhere database format, complete with the following data improvements:

- Instruments and instrument profiles

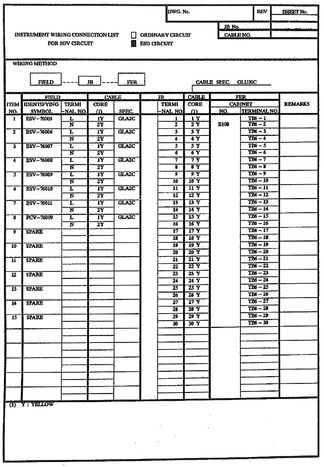

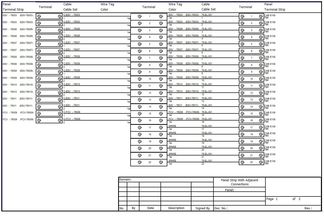

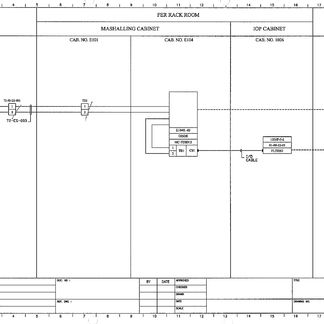

- Cabling and wiring equipment

- Enhanced panel strip report

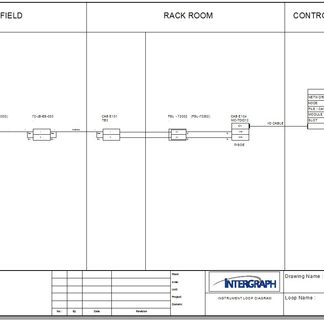

- Enhanced SmartLoops

- Support for configuration of SmartPlant Instrumentation access rights

Work Process

The import and conversion of wiring and loop drawings follows these steps:

- Perform a study of the existing wiring documentation

- Development of import and wiring strategy

- Development of SPI seed database according to client standards

- Creating reference catalogue

- Instrument, Wiring Equipment, Cabinet and Cable creation

- Input/output Assignment

- Development of drawing Templates

- Loop drawing and Wiring Diagram creation.

Quality Assurance

TecSurge takes pride in its quality of work. Quality assurance takes place at every step of the conversion process and at the final stages.

Drawing Quality

Loop drawing and Wiring Diagram conversion involves a semi-automatic process. Although wiring data can be imported, the intricate nature of instrumentation usually prevents a fully automated approach, and so wiring is still performed manually to make sure it matches the intended design.

Data capturing to device information (e.g. manufacturer and model) that can be loaded into the database are checked directly at the source prior to import. After the loading process, the data is again compared to the import source to make sure that the information is accurately loaded in SPI.

Loop drawings and Wiring Diagrams cannot be checked automatically. Once the drawings are generated, our team of experts does an exhaustive check to confirm that connections are identical to the original drawings.

Database Quality

During the course of the project, TecSurge runs the in-built SPI database checker to identify and eliminate any problems. All errors are rectified to maintain a healthy database.

Prior to final handover, the SPI database is re-checked for faults and the check log generated. The log file is provided to the client as part of the handover.

Getting Started

In order to start the process, we will require the following information:

-

What is the SPI version including service pack and hotfix required?

Why: This information is important in order to identify the specific requirement of the client.

-

Database server used?

Why: We mimic the client’s environment in our system in order to carry out a full check and make sure full compatibility is achieved.

-

Sample Loop drawings and Connection diagrams?

Why: Sample drawings will tell us the most efficient way to implement the conversion as well recommend options to the client. This will also give us some insights on the quality of source data that needs to be will processed.

-

Quantity of Loop drawings, Wiring Diagrams, Instruments, Junction Boxes and Cabinets?

Why: The quantity of this objects will determine the effort required for the conversion. This will also help us check if automation can be applied to lessen the time required and therefore reduce costs for the client.

The following information may be requested depending on the situation:

-

Do you require assistance to restore the SPI database in your environment and execute post restoration procedures?

Why: In the event that the client does not have a qualified personnel for this task, TecSurge can provide support in restoring the database in the client environment ensuring a smooth handover of the database.

If this service describes your situation, and you’re able to provide the engineering inputs and answers to the questions listed here, contact us today for a quotation on Wiring Diagram and Loop drawing conversion for SPI.