Structural Joints for AVEVA E3D

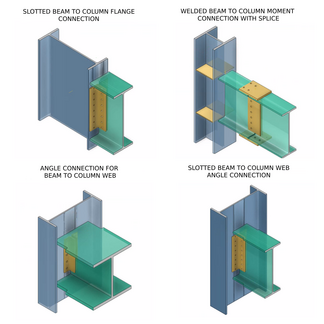

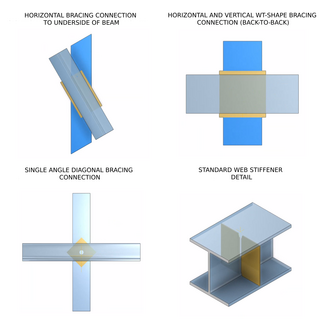

Symbols and Assemblies

Introduction

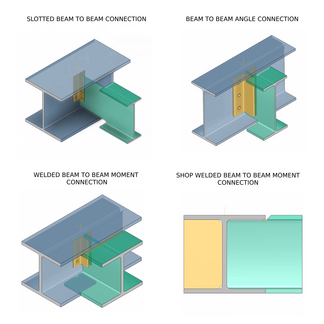

This service focuses on the development and customization of structural joints for AVEVA E3D which adhere to client-specific or industry standards. The service covers a full range of requirements, supporting the creation of both single and merged joints using advanced design templates and PML (Programmable Macro Language), ensuring that the structural joints are compatible with provided standards.

Summary

We categorize each structural connection into specifications based on client requirements and applicable standards. Connections are selected from customized templates and seamlessly integrated into the structure using the AVEVA programmable macro language (PML).

Our expertise covers the entire process of structural joint creation, from the initial integration of standards to the final validation and documentation. We specialize in customizing joint designs to meet the specific requirements of each project, ensuring that every joint we create is fit for purpose and adheres to the relevant regulations. Additionally, our process utilizes a comprehensive specification system to drive joint selection, ensuring alignment with project-specific needs and standards.

Differentiators

- Guidance: We provide step-by-step guidance for implementing structural joints that align with various engineering standards, helping clients navigate complex specifications.

- Development: We develop flexible joint families using AVEVA E3D design templates and PML, ensuring that the joints can be tailored to specific project needs and reused across different standards.

- Delivery: We deliver fully validated joint designs, ready for use in the project, with comprehensive documentation for future reference.

- Resources: Our team of experts is well-versed in PML programming and AVEVA E3D, ensuring that each joint is optimized for performance and compliance.

Deliverables

We create structural joints by leveraging AVEVA E3D’s design templates and programmable macro language (PML) to develop joint families that comply with a variety of standards. Each joint is designed for adaptability, allowing for reuse across projects and different structural codes. Our primary deliverables consist of custom structural joints tailored to meet diverse structural standards, ensuring flexibility and compliance for all applications.

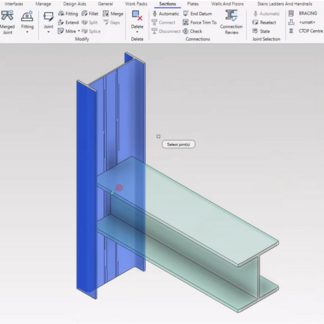

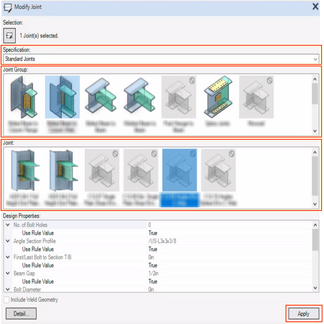

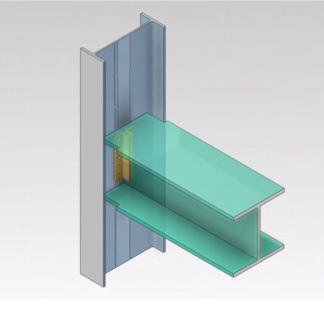

Joint Modelling in AVEVA E3D

- Selection of structural member to where joint will be connected.

- Selection of the appropriate structural joint based on the connection requirements.

- Once "Apply" is clicked, the joint will be automatically attached to the structure.

Work Process

We follow a structured process to ensure that the creation of structural joints in AVEVA E3D is efficient and standards-compliant:

- Phase 1: Initial consultation to understand the client’s standards or the required industry standard for joint creation.

- Phase 2: Development of design templates and PML-based joint families, ensuring flexibility for reuse across different standards.

- Phase 3: Customization of the joints for both single and merged configurations, making them adaptable for complex projects.

- Phase 4: Simulation and testing to ensure the joint families comply with all necessary structural requirements.

- Phase 5: Final validation, documentation, and delivery of the joint families, with ongoing support if needed.

Once the joint families are created, they undergo a thorough validation process, ensuring their compliance with the relevant standards and their performance under different structural conditions. This ensures that each joint can be implemented seamlessly into the client’s project.

Quality Assurance

TecSurge ensures the quality of each structural joint by using a rigorous quality control process that involves detailed simulation and analysis within AVEVA E3D. This ensures that each joint not only meets compliance but also performs optimally in real-world applications.

Our team manages the validation process through thorough testing and review, ensuring that all joints are robust, reliable, and compliant with the relevant standards. The quality assurance process also includes a final review to ensure that the joint families can be reused across various standards without compromising integrity.

Getting Started

TecSurge is engaged early in the project lifecycle to ensure that all client requirements are understood, allowing us to customize our services to meet the specific needs of your project. Our approach ensures that we deliver high-quality structural joints that are tailored to the exacting standards of your project.

To understand the scope of the work, we ask a series of questions, such as:

- What are the specific standards or client-specific requirements for the structural joints?

Why: This information is crucial for configuring the AVEVA E3D environment and developing joint families that meet the necessary standards. - What types of structural joints are required, including both single and merged configurations?

Why: We customize the joint designs based on the complexity and type of connections required, ensuring they fit seamlessly within the project’s structural framework. - When is your target completion date, and when do you expect to start?

Why: Understanding these parameters helps us allocate resources efficiently, manage timelines effectively, and adjust the scope of work based on project needs.

If this service describes your situation, and you’re able to provide the engineering inputs and answers to the questions listed here, contact us today for Structural Joints Creation in AVEVA E3D.