Draft and Isodraft Setup for PDMS/E3D

Drawings, reports and datasheets

Summary

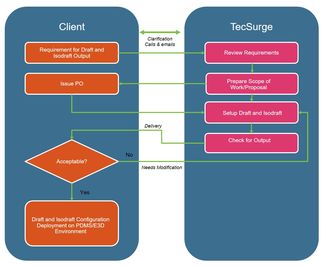

Under this service, TecSurge prepares and delivers settings and configurations for use with the AVEVA PDMS/Everything3D Draft and Isodraft modules.

Differentiators

- Extensive experience working with plant design deliverables.

- Excellent technical and functional knowledge of PDMS/E3D Draft and Isodraft

- Designer-driven quality assurance process

Deliverables

The typical deliverables produced by this service are:

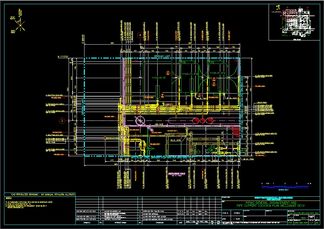

- Draft Libraries, Symbols and Templates for arrangement and layout drawings

- Automatic Drawing Production (ADP) general and area-based settings

Work Process

TecSurge manages the execution of Draft and Isodraft Setup as a professional services project involving a dedicated project manager and our expert service team.

PDMS Draft setup detailed execution stages

- Review of client standards and specifications

- Configuration of Draft & Isodraft settings

- Testing and output validation

Review of client standards and specifications

Before starting the project, standards and specifications provided by our client are reviewed, and any suggestions or clarifications resolved collaboratively. This step ensures that there is enough information to complete the project, and that client expectations for deliverables will be met by the resulting configuration. Documents may include technical requirements for drawings (line style, colours, and font), hierarchy, naming rules, and others.

Configuration of Draft and Isodraft settings

For Draft setup, the following elements are configured:

- Draft Default Settings

- Working Library Selection

- Sheet Library

- Symbol Library

- 2D Symbol Representation

- Label Library

- Style Library

- Representation Library

- Drawlist Library

- Tag Rule Library

- Automatic Drawing Production (ADP)

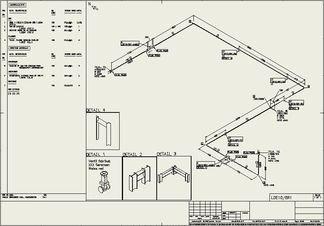

For Isodraft setup, the following elements are configured:

- Isodraft Symboly Library

- Backing Sheet

- Option File

Testing and Output Validation

Once configuration is completed, sample drawings are generated using a a variety of layouts and orientations. The generated deliverables are then reviewed and compared with input client requirements. If any adjustments to configuration are required, these are made and the process repeated until the deliverables match the specifications.

Quality Assurance

TecSurge ensures that all deliverables are checked and verified according to their requirements and the output is tested on every layout required by client.

During the customer verification period, the client confirms their acceptance of each of the deliverables and provides comments or feedback regarding the delivered package. Any issues raised during this stage will be resolved prior to project completion.

Getting Started

Typically, our customers must prepare input data/documents, such as piping assembly standards, PDMS piping specs and catalogues that are required to start the project. TecSurge validates all the input data.

In addition to these documents which are requested by TecSurge, we will ask our clients a series of questions to clarify the scope of work:

-

What version of PDMS/E3D are you using?

Why: To account for full compatibility on different versions of PDMS/E3D and ensure our testing is performed on an environment required by our client.

-

When is your target completion date, and when do you expect to start?

Why: The responses to these standard project management parameters can have a significant impact on the cost due to the prioritisation of work and the manpower required.

If this service describes your situation, and you’re able to provide the engineering inputs and answers to the questions listed here, contact us today for a quotation.