PDMS / E3D Spooler Setup

Drawings, reports and datasheets

Summary

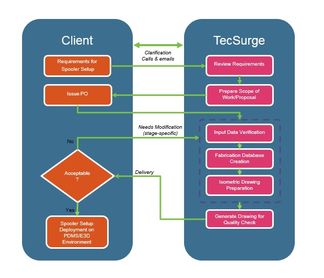

Under this service, TecSurge prepares, tests and delivers configuration files and settings for use with AVEVA PDMS/E3D Spooler module.

Differentiators

- Long experience working with both EPC and owner-operator organizations

- Excellent technical and functional knowledge of PDMS/E3D Spooler

- Reliable setup with minimum effort

Deliverables

The typical deliverables produced by this service are:

- Spooler settings (including Default Files and Fabrication Database)

- Isometric Drawing settings (including Option files, Backing Sheets)

Work Process

TecSurge manages the execution of Spooler setup as a professional service project involving our expert services team.

The detailed execution consists of several stages:

- Fabrication Database Creation

- Isometric Drawing Preparation

Fabrication Database Creation

Before the users can split pipework design into spools and store spool data, a Fabrication Database must be created in the Admin module.

The Fabrication Database will then be added to the MDB and will hold the pipework spool drawings generated by the Spooler module.

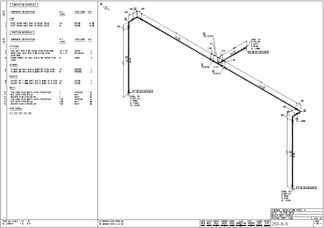

Isometric Drawing Preparation

The following must be set before users can extract isometric drawings from fabrication database:

-

Isodraft symbol library

Preparation of user-definable drawing symbols for piping components in isometric drawing

-

Backing Sheet

Preparation of project-specific drawing template plot file as isometric backing sheet

-

Options File

Isodraft options settings in a text file

Quality Assurance

TecSurge ensures that prior to issue of deliverables, Spooler setup must be tested in PDMS test environment. TecSurge also ensures all the deliverables are in accordance to the verified input data provided by client. Generating sample isometric drawings using standard application are done for quality checking. Upon successful testing and checking, the handover package is sent for customer verification.

Then client confirms their acceptance of the catalogues and specifications and provides comments and feedbacks. Any issues raised during this stage will be resolved until final handover is completed.

Getting Started

Typically, our clients must prepare all the input data such as backing sheet, title block and symbols that is required to start the project. TecSurge takes care of checking and validating all the input data. In addition to the required data which is requested by TecSurge, we will ask our clients a series of questions to clarify the scope of work:

- What version of PDMS/E3D are you using?

- Why: To account for full compatibility on different versions of PDMS/E3D and ensure our testing is performed on an environment required by our client.

- When is your target completion date, and when do you expect to start?

- Why: The responses to these standard project management parameters can have a significant impact on the cost due to the prioritisation of work and the manpower required.

If this service describes your situation, and you’re able to provide the engineering inputs and answers to the questions listed here, contact us today for a quotation.