Intelligent 3D Back-modelling

Data Migration and Transformation

Summary

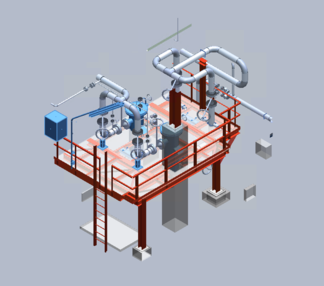

TecSurge delivers a fully intelligent, high fidelity 3D model representing the as-is state of the plant, by using all available inputs including existing model data, existing drawings & documentation, and point clouds and photographs captured by laser scanning.

Benefits

Our approach delivers the combined benefits of an intelligent model migration with as-building to reflect the as-is state of the plant. The resulting model is fully intelligent and high-fidelity, making it suitable to be used for ongoing plant modification and maintenance without additional remediation.

Differentiators

TecSurge provides all the competencies required to efficiently back-model 3D plant models from information sources such as:

- P&IDs, orthographic drawings, and piping isometrics

- 3D plant models regardless of format

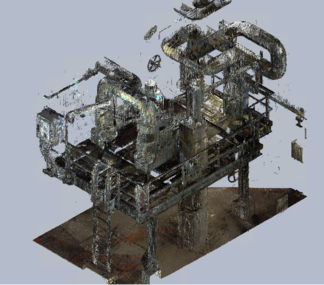

- Point clouds and photographs captured by laser scanning

- Specifications and datasheets

Work Process

We leverage our expertise with automation to migrate data from any existing sources such as 3D models and intelligent piping isometrics to extract as much value as possible from legacy data sets.

Embedded or composite elements such as equipment packages can optionally be remodelled to improve performance and broken down to incorporate proper plant numbering systems and tags.

Our experienced engineers and designers then reference existing plant drawings and documentation, combined with as-built data captured through laser scanning to prepare and update the plant model to match current conditions. Our familiarity with modern laser scanning software ensures any deviations between existing documentation and the as-is state are identified, clarified, and resolved before delivery.

Specifications, catalogues, and datasheets are analysed and compared with as-built data, and any deviations escalated for review. Based on feedback and approval, application specifications, catalogues and symbols are revised to reflect the as-built condition.

Deliverables

At project commencement, we configure our environment using reference data provided by the client and provision the agreed version of the target plant design application to ensure a smooth delivery. Upon completion, a full backup of the plant design environment, including all specifications, catalogues, symbols, drawings, quality reports, and the model itself are prepared and issued to be restored or merged into the destination environment.

Quality Assurance

We validate our results by proactively applying application functionality such as:

- Connectivity and consistency functionality such as “to-do” lists

- Orthographic drawing and piping isometric generation

- Report extraction for comparison with external data sources

- Publishing visualization models for progress reporting and client review

Getting Started

To make a full and accurate estimate of the effort, TecSurge relies on the information provided in three different forms:

- Consultative discussion regarding the overall fidelity and scope requirements

- Detailed quantitative and scoping factors captured in a questionnaire.

- Access to the source specifications, models, and drawing data.

If this service describes your situation, please contact us today for a quotation.