Intergraph Smart P&ID Conversion

Data Migration and Transformation

Summary

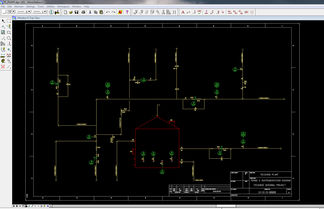

This service converts P&IDs from formats such as MicroStation or AutoCAD to Intergraph Smart P&ID.

Differentiators

- Extensive Intergraph Smart P&ID expertise and experience

- Advanced application knowledge accelerates delivery

- Best practice knowledge and consulting advice

Challenges

The conversion of existing P&IDs is a complex activity key to deriving value from the Intergraph Smart P&ID solution. Manual transformation of CAD drawings into intelligent data is inefficient and prone to human error.

Deliverables

In a typical project, we deliver a project archive from Intergraph Smart P&ID containing the reference data, configuration, P&ID drawings and data. PDF renditions of drawings can also be provided for incorporation into traditional document management systems.

Work Process

Our work process typically incorporates the following activities:

- Configure the Smart P&ID software, reference data and database to meet client or project requirements and standards, including:

- Plant Breakdown Structure

- Plant Options

- Naming Conventions

- Data Dictionary and attribute requirements

- Symbol Catalogues and Assemblies

- Drawing, Datasheet and Report Templates

- Create intelligent P&ID drawings by populating the database with information such as drawing title block data, tags and attribute data from existing electronic sources.

- Import and map high-fidelity CAD elements to intelligent P&ID symbols using custom in-house automation tools

- Complete P&ID migration using manual methods for elements which are not cost-effectively handled through automation

- Extract reports and snapshot drawings to perform quality checks and corrections

- Submit a project archive, reports and drawings to the client for review

- Conduct final project handover and production deployment into the client environment

Quality Assurance

TecSurge uses a combination of peer review and automated data and rule checks to verify the quality of our workmanship. A final check involves one-for-one comparison of each completed P&ID against its source, to ensure an accurate and complete reproduction is produced.

In addition, we extract all drawings and relevant reports for review by our client prior to incorporating the new or modified drawings into the production environment, to reduce any risks of misinterpretation and to minimize disruption to ongoing operations.

Getting Started

To estimate the schedule and cost for this service, we typically request the following preliminary information:

-

What is the target software and database version?

Why: We reproduce the target environment locally to ensure full compatibility with your environment is maintained.

-

What are the standards, templates and existing drawings you will provide?

Why: Input based upon industry standards typically take less time, while those based upon vendor or non-standard systems may require additional effort.

-

What is the target completion date?

Why: Usually revisions are required within a short time frame. To ensure success, we agree a defined target date for the project completion up-front.

If this service describes your situation, and you’re able to provide the engineering inputs and answers to the questions listed here, contact us today for a quotation.