PDMS Piping Assemblies

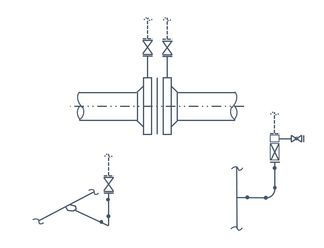

Symbols and Assemblies

Summary

Under this service TecSurge creates and delivers piping assemblies for use in PDMS 3D modelling in accordance with verified piping assembly standards provided by our clients.

Differentiators

- Delivery to tight project schedules without compromising the quality of work

- Deep understanding of piping assembly systems for different industries

- Efficiency and accuracy achieved using piping assembly for placing of individual components

Deliverables

The primary deliverables from this service are:

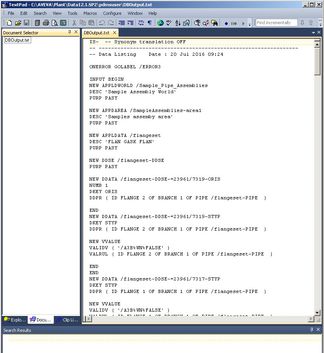

- Macro text files in DATAL (Data Listing) format

- Documentation with illustration of each assembly

Work Process

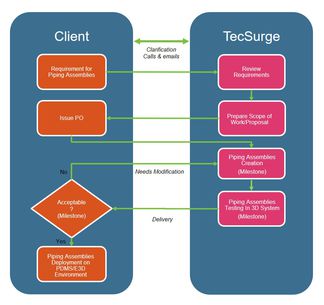

TecSurge manages the execution of piping assembly as a professional project involving a dedicated project manager and our expert services team. Typically, the project schedule will be organised and based upon milestones aligned with our client’s project priorities. For example, piping assemblies that are commonly used are prioritized and will be delivered first.

These priorities and deliverables associated with each of the project milestones are agreed with the client during the project kick-off meeting, after which the detailed execution commences.

As each milestone is reached, a set of completed and quality checked piping assemblies is delivered, along with a project status report.

Detailed stages of execution are:

- Piping assembly standard verification

- Check if all components are available in piping specs

- Piping assembly creation

- Using Piping Assembly Manager in PDMS (standard assembly)

- Non-Graphical Assemblies using customised PML (Programmable Macro Language)

- Testing and validating components and dimensions

Piping assembly standard verification

The piping assembly standard will be verified before starting the project. This verification ensures that enough information is available in the assembly standard for the creation of piping assembly in PDMS/E3D.

Check that all components are available in piping specs

After the piping assembly standard has been checked, the components of the piping assembly will be checked in all piping specs to ensure that all components are available and to make sure the assembly will work.

Piping assembly creation

A hierarchy will be created for the piping assembly as follows:

- APPLDW (Application Data World – Assembly World) – The topmost hierarchy and can be created in a separate DB or the DB shared with piping.

- APPDAR (Application Data Area – Assembly Area Element) – This level is used for grouping of piping assemblies by area or by type.

- APPLDA (Application Data – Assembly). This level represents the owning element of each piping assembly.

Below are the two approaches used in creating the assemblies.

-

Using Piping Assembly Manager in PDMS:

The piping assemblies can be created based on assemblies modelled in PDMS per piping assembly standard. Rules can be applied to the assembly to refine the selection of components or apply conditions with some limitations.

-

Non-Graphical Assemblies using customised PML:

This option offers more flexibility and functionality than the piping assembly manager. Certain conditions are coded in PML to ensure requirements are met by the piping assembly.

Testing and validating components and dimensions

All assemblies are tested to ensure that each is in accordance with the piping assembly standard. Testing will include placing the assembly at different orientations, checking its dimensions and checking the isometric output.

Quality Assurance

TecSurge ensures that all the piping assemblies are tested in all possible scenarios. Upon successful completion, the handover package is sent for customer verification.

During the customer verification period, the client confirms their acceptance of each piping assembly type and provides comments or feedback regarding the delivered package. Any issues raised during this stage will be resolved prior to final handover.

Getting Started

Typically, our customers prepare the input data/documents, such as piping assembly standards, PDMS piping specs and catalogues, which are required to start the project. TecSurge checks and validates all the input data.

In addition to these documents which are requested by TecSurge, we will ask our clients a series of questions to clarify the scope of work:

- What version of PDMS/E3D are you using?

- Why: To account for full compatibility on different versions of PDMS/E3D and ensure our testing is performed on an environment required by our client.

- When is your target completion date, and when do you expect to start?

- Why: The responses to these standard project management parameters can have a significant impact on the cost due to the prioritisation of work and the manpower required.

If this service describes your situation, and you’re able to provide the engineering inputs and answers to the questions listed here, contact us today for a quotation.