Piping Specification Conversion

Specification and Catalogues

Summary

This service delivers piping specification data for a target system by converting from a source system. Typical conversions include from Intergraph PDS to Smart 3D and AVEVA PDMS to Smart 3D, however other systems such as CADWorx, AutoCAD Plant 3D, Bentley OpenPlant and AutoPLANT and combinations thereof are also supported. TecSurge uses in-house expertise with piping specifications and plant design software and applies custom automation technology to deliver a high-quality result and accelerated schedule.

Client requirements for Piping Specification Conversion often arise from corresponding Plant Model Migration projects, but other scenarios such as implementation of a new plant design system are also possible.

Differentiators

- High-quality, “right first time” results, due to automation and thorough quality control

- Schedule and priority driven by actual model requirements, allowing incremental delivery and supporting accelerated Plant Model Migration projects

- Verification of source and target catalogue dimensional data (e.g., face to face dimensions) enables reliable Plant Model Migration

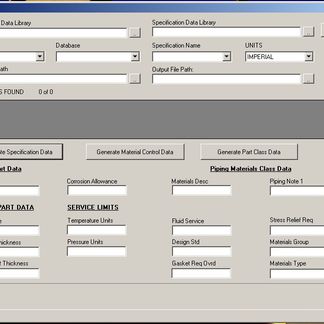

- Option to utilise and convert via SmartPlant Reference Data Deliverables

Deliverables

The primary deliverables from this service consist of data files which can be imported directly into the target plant design systems, such as:

- Excel bulk load sheets for Smart 3D

- PCD, PMC and description library text files for PDS

- SPECON load files for PDMS

- Pspx, pspc, pcat and dwg files for AutoCAD Plant 3D

- Microsoft Access database files for OpenPlant and AutoPLANT

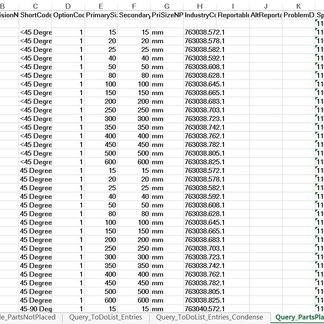

Using Smart 3D as an example of a target system, the Excel format bulk load sheets include specific data such as Code lists, Plant Rules, Specification Data, Material Control Data and Part Class Data. Database snapshots backup files are also provided in this case.

Deliverables are provided in both full and incremental form at project milestones designed to suit associated Plant Model Migration project schedule requirements.

Work Process

Delivery milestones are scheduled according to input dependencies and priorities defined by the client. Where the Piping Specification Conversion is being performed to enable a Plant Model Migration project, these priorities are often structured to maximise the efficiency of the dependent project. In this case, piping specifications are prioritised in decreasing order based upon their utilisation in the source plant model, such that delivery of the first few specifications enables the migration of a large proportion of the model.

Where the Piping Specification Conversion does not have any associated migration dependencies, TecSurge will prioritise and sequence the delivery in collaboration with the client.

The workflow either follows a “direct” conversion from one source system to another, or an “indirect” conversion using SmartPlant Reference Data as the system of record and intermediate form.

TecSurge utilises in-house technology to accelerate the conversion process and ensure a high-quality result. This enables the import of source PDS or PDMS specification data and automation of a proportion of the conversion to the target format. Due to fundamental differences between systems, some additional manual effort is almost always necessary to complete the conversion, work which is performed by our piping specification specialists and Service Operation Centre.

Quality Assurance

TecSurge guarantees that the specifications converted for use in the target system are 100% ready for use and match the source data provided. In-house utilities are used to ensure that all components from the source system are available in the target.

TecSurge also utilises standard application verification functionality, and 3rd party tools such as CAXperts SpecXpert to perform placement testing in target systems such as PDS and S3D.

Getting Started

There are two common situations for which the Piping Specification Conversion service is commonly required:

- Where a Plant Model Migration project is to be undertaken

- Where a company is implementing a new plant design system to replace an existing solution

In both cases, the end requirement to convert the existing piping specification data into a format suitable for the target system is the same, however the priorities and scheduling constraints for each scenario can be substantially different.

TecSurge will request that the piping specification data from the source system be provided in its native format, along with any associated engineering specifications, standards, and data sheets. For the model migration case, existing plant model data will also be requested to suggest the most efficient delivery schedule.

| Source System | Source Data Types |

|---|---|

| PDS | Reference database (including PMC, PCD and other tables) Specification and physical data library Short description library |

| PDMS | SPEC, CATA, COCO, SMTE and CMPW data files |

Based upon the source data provided, TecSurge will prepare a schedule and quotation for approval, after which our expert team will perform the conversion work and deliver the converted and quality tested result.

If this service description matches the business problem you’re trying to solve, contact us today for a quotation for Piping Specification Conversion.