MDS (Multi Discipline Support) Setup for PDMS/E3D

Systems implementation and integration

Summary

This TecSurge service delivers Multi Discipline Support (MDS) setup for AVEVA PDMS/E3D. MDS is the equivalent of Hangers and Supports in S3D. The service delivery includes:

- MDS database settings in the Administration module,

- Standard support catalogue/template creation in accordance with the reference support standard, and

- Automatic drawing production setup in accordance with the support detail drawing requirement.

The support standard and support detail drawing requirements provided by customers are verified for the consistency and accuracy of input data.

The support catalogues and templates are designed to allow support designers to create standard supports for pipework, HVAC and cable trays, including both piping based cable trays [BRAN type] and cable trays [CTRAY type] created by the cabling system.

Differentiators

- Minimized delivery schedule and cost

- Minimum effort in setup

- Quality assured

Deliverables

The typical deliverables produced by this service are:

- MDS Project Settings (including Default files and MDS Databases)

- Ancillary Support Catalogue Creation and Settings (including Shoes, Clamps, Lug, U-Bolt, Anchor, Guide and Stops)

- Secondary Support Templates and Settings (including Cantilever Bracket, T-Post, L-Type and Goal Posts)

- Hanger Support Templates and Settings (including Variable and Fixed Types)

- Lighting Support Templates and Settings (including Support frameworks for electrical light fittings)

- Trunnion Settings (including Stanchion, Stanchion on Tee and Stanchion on Elbow)

- Automatic Drawing Production Setup (including Representation, Styles and Symbol Library, and Drawing Templates)

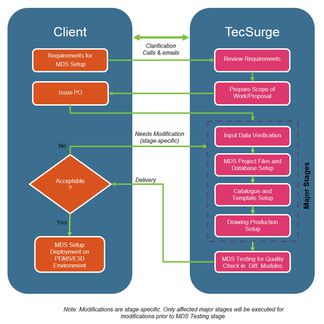

Work Process

TecSurge manages the execution of Multi Discipline Support setup as a professional service project involving a dedicated manager and our expert services team. Typically, the project schedule will be organised and based upon project milestones aligned with our client’s project priorities.

These priorities and deliverables associated with each of the project milestones are agreed with the client during the project kick-off meeting, after which the detailed execution commences.

The detailed execution consists of several stages:

- Reference documents and Input data verification

- MDS Project Files and Databases setup

- Catalogue and Template elements setup

- Drawing Production setup

- MDS testing in different modules

Reference documents and Input Data Verification

The support standard is carefully verified for sufficient details to complete the catalogue and template elements. Element naming conventions and support detail drawing requirements are verified before setting up the support auto-naming and automatic drawing production settings.

Clarifications or missing information will be requested from our customer prior to the commencement of the next stage.

MDS Project Files and Databases setup

In every project, there are corresponding files to be setup in the project folder location. These files may include PML library files, auto-naming and report default files.

The databases used are supplied from the MDS/MDU project, which can be controlled centrally from an MDS/MDU project to be included as foreign databases in client project, or as reconfigured copies of databases from MDS project to the client project. These databases may contain the MDS Catalogue & Specifications, hanger and framework templates, DRAFT libraries and User Defined Attributes for MDS applications.

Catalogue/Template elements setup

Ancillary support types such as lugs, U-bolts, anchors, stops, guides and plates are configured geometrically using the customizable sets of category element (CATE) from the AVEVA supplied catalogue which can be modified in the PARAGON module.

Secondary support templates are configured using AVEVA supplied templates with British Standard as the default steelwork standard which can be modified for sizes in Design module under Site /MDS/TEMPLATES. For every secondary support type, there is a corresponding zone element (ZONE) with structure members (STRU) as the steelwork sizes.

Hanger support templates are configured using AVEVA supplied templates under Site /MDS/HANGERS. Manufacturer templates are available for use from CPL (Carpenter & Paterson Ltd), PSL (PS Designer), LIS (Lisega) or standard MDS hanger project catalogue databases.

Lighting support templates are configured using templates created under Zone /MDS/SPECIAL/LIGHTING. These templates are of type STRU which are created using standard structural modelling.

Drawing production setup

Drawing template and task using Area Based Automatic Drawing Production (ADP) application are configured in the DRAFT module for support detail drawing generation. Representation rules and styles are based on support detail drawing requirement supplied by the customer.

MDS Testing

To verify the MDS setup is working properly, TecSurge performs a series of quality tests and checks in different modules.

- Model of each support type

- All ancillary support for verification of geometry

- All secondary, trunnion, hanger and lighting support for verification of correct sizes and configuration

- Draft of secondary, trunnion and hanger support

- Verification for overall drawing requirement which includes representation, dimensioning and Material Take-Off

After successful setup and test, a project status report is delivered to the client.

Quality Assurance

TecSurge ensures that prior to issuing deliverables, the MDS setup is fully functional and meets our client expectations. TecSurge also ensures all the deliverables are in accordance to the verified input data provided by the client.

Support modelling testing and sample support detail drawings using standard application functions are incorporated in to the quality process. Upon successful testing and checking, the handover package is sent for customer verification. The client then confirms acceptance of the MDS setup or provides comments and feedback. Any issues raised during this stage will be resolved prior to final handover and project completion.

Getting Started

Typically, our clients will prepare all the input data/documents, such as support standard, support naming conventions and support detail drawing requirements that are required to start the project. TecSurge validates all the input data and confirms that it contains all the necessary information, such as dimension, material and member sizes.

In addition to these project requirements, we will ask our clients a series of questions to clarify the scope of work:

- What version of PDMS/E3D are you using?

- Why: To account for full compatibility on different versions of PDMS/E3D and ensure our testing is performed on an environment required by our client.

- What types of support catalogues are required?

- Why: Some of the support types may require additional effort like secondary and trunnion supports as it is using a conventional method compared to ancillary support.

- When is your target completion date, and when do you expect to start?

- Why: The responses to these standard project management parameters can have a significant impact on the cost due to the prioritisation of work and the manpower required.

If this service describes your situation, and you’re able to provide the engineering inputs and answers to the questions listed here, contact us today for a quotation.